OUR SPECIALIZATION

We offer comprehensive PCB Assembly services, including both SMT (Surface Mount Technology) and THT (Through-Hole Technology), ensuring precision and reliability. Our End-to-End Product Design capabilities bring ideas to life, from concept to final product. With advanced Prototyping & Testing, we validate performance early, reducing risks and time-to-market. Our Box Build & System Integration solutions deliver complete, ready-to-use electronic systems tailored to your needs.

READ MORE DETAILS BELOW

From idea to implementation, we provide complete, dependable electronics manufacturing services tailored to your goals. Partner with us to bring your vision to life—efficiently, expertly, and on time.

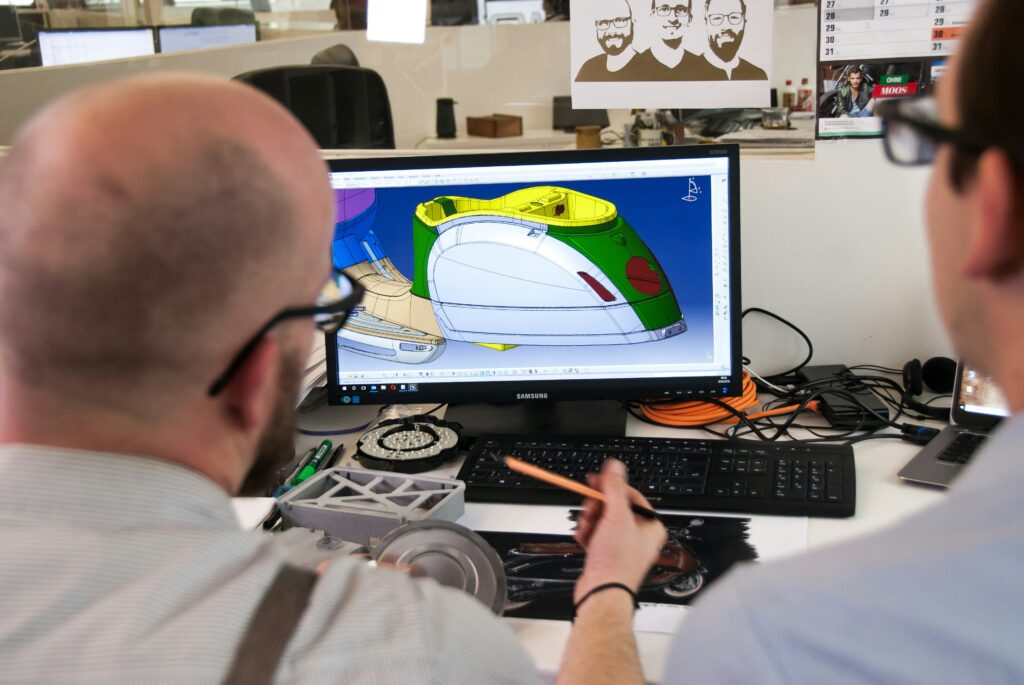

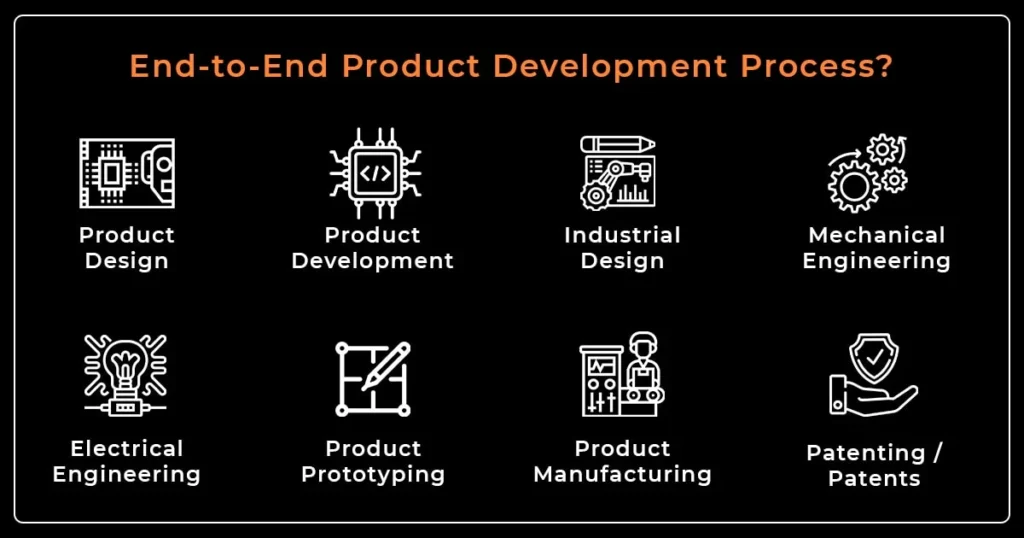

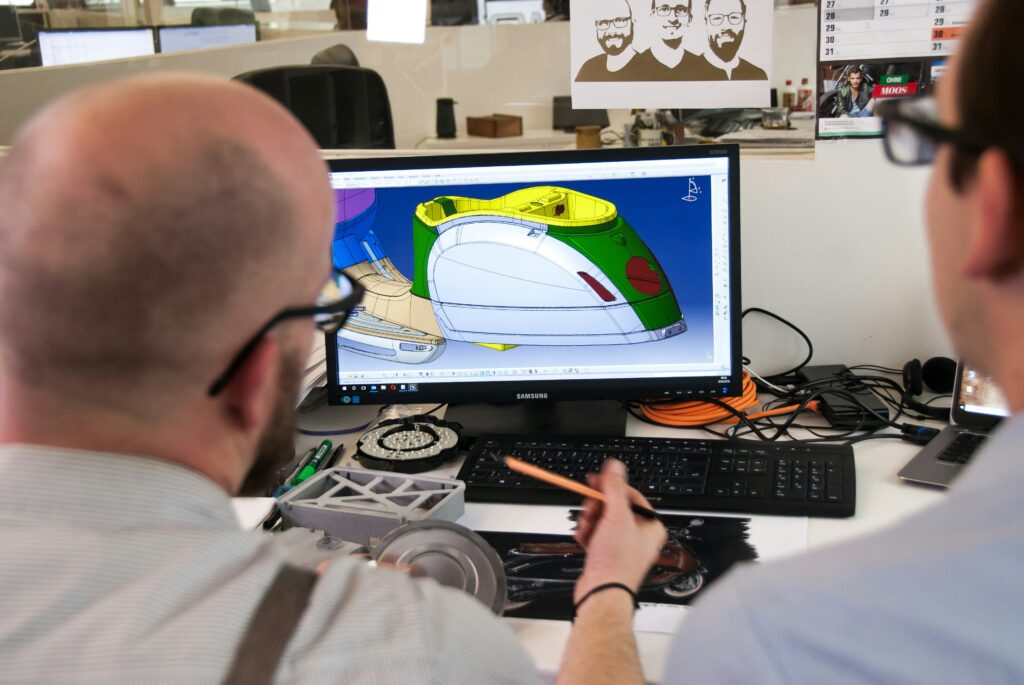

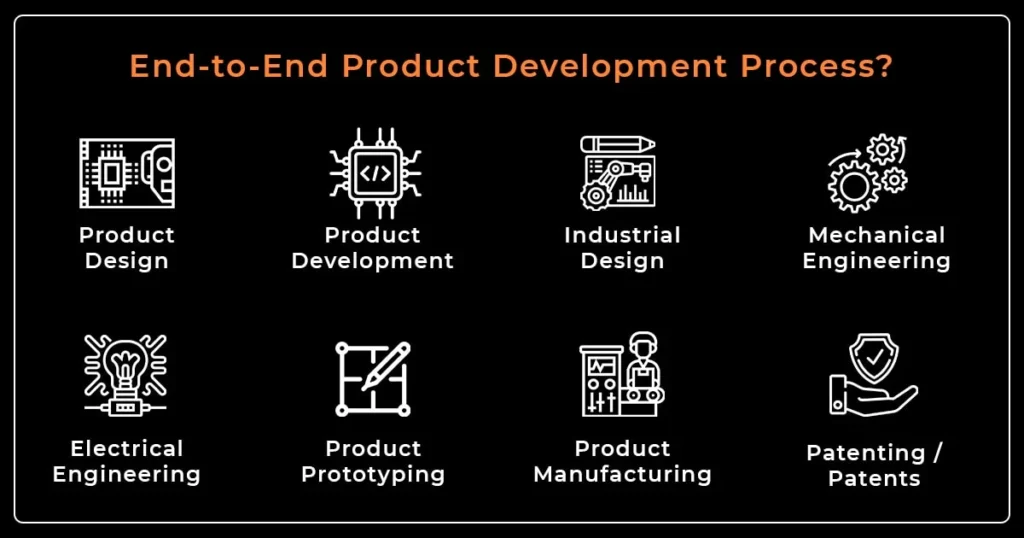

End-to-End Product Design

We offer comprehensive product design services that take your idea from initial concept to full-scale production. Our experienced team manages every phase of development—including product ideation, schematic and circuit design, PCB layout, 3D modeling, prototyping, firmware and embedded software development, mechanical design, and system-level integration. With a strong focus on performance, manufacturability, and cost-efficiency, we ensure your product is not only functional and reliable but also optimized for market success. Whether you’re developing a new innovation or refining an existing product, we provide the technical expertise and cross-functional collaboration needed to bring your vision to life.

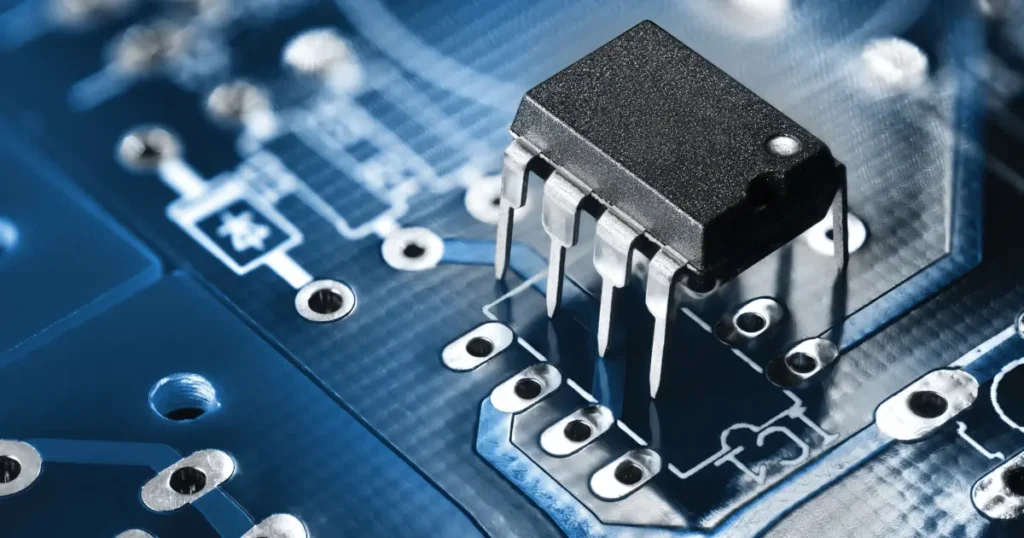

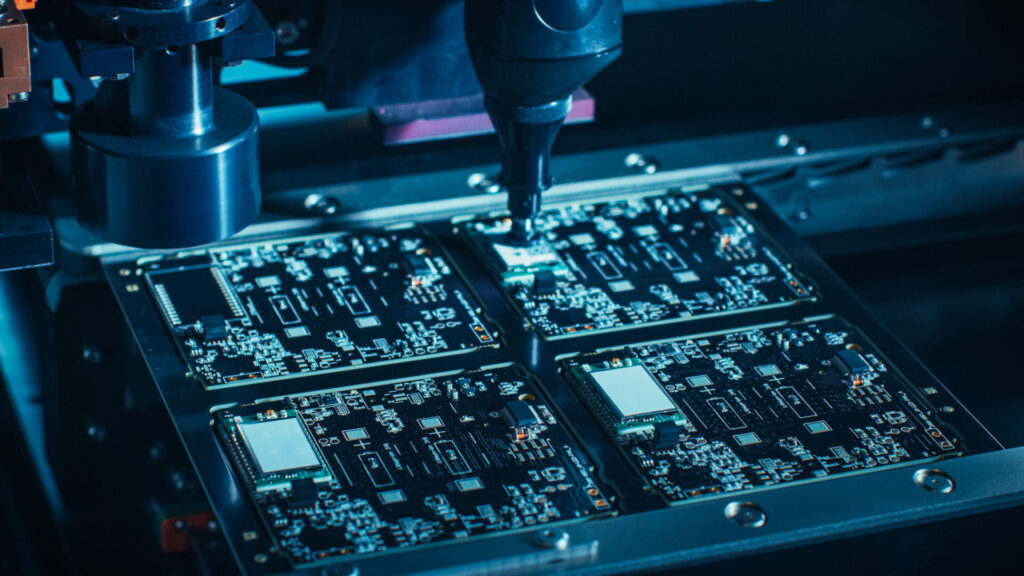

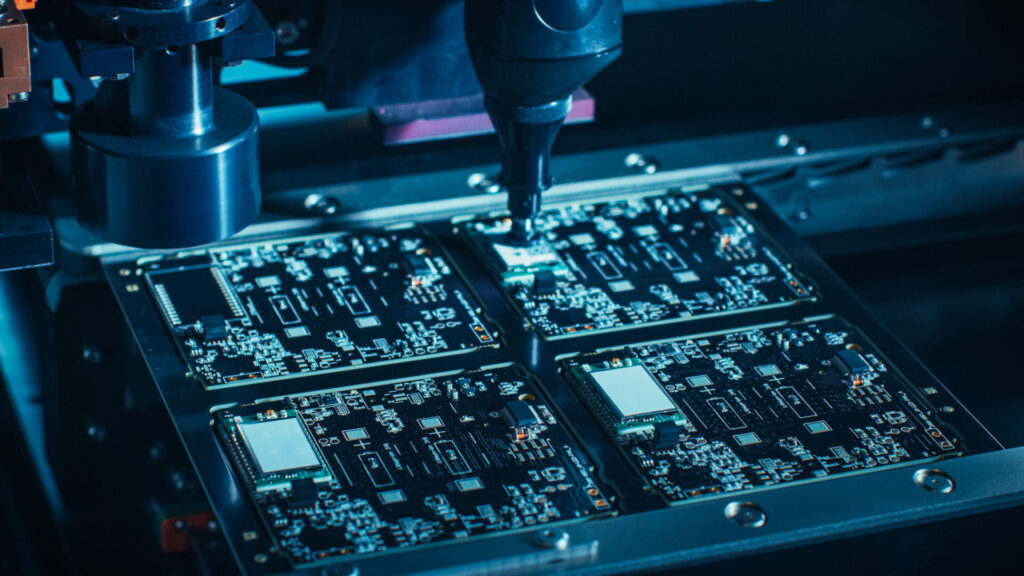

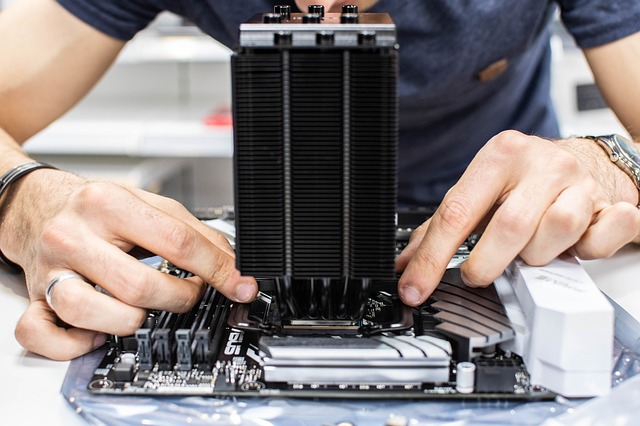

PCB Assembly (SMT & THT)

We provide end-to-end PCB assembly services utilizing both Surface Mount Technology (SMT) and Through-Hole Technology (THT) to meet a wide range of design and production needs. Our advanced manufacturing setup enables accurate component placement, automated soldering processes, and strict quality control. From single prototypes to large-scale production runs, we ensure every board meets the highest standards of reliability and performance. Our expertise spans double-sided assemblies, mixed-technology boards, fine-pitch components, and RoHS compliance—delivering cost-effective, timely solutions tailored to your product requirements.

Box Build & System Integration

We provide comprehensive box build and system integration services that go beyond PCB assembly to deliver fully assembled, ready-to-deploy electronic systems. Our capabilities include enclosure assembly, cable and wire harness installation, sub-system integration, thermal management, labeling, and final functional and quality testing. Whether it’s a simple product enclosure or a complex electromechanical system, we manage the entire process—from component sourcing to final packaging—with a strong focus on precision, scalability, and reliability. Our turnkey solutions are customized to meet your unique technical and commercial requirements, helping you reduce time-to-market and streamline production workflows.

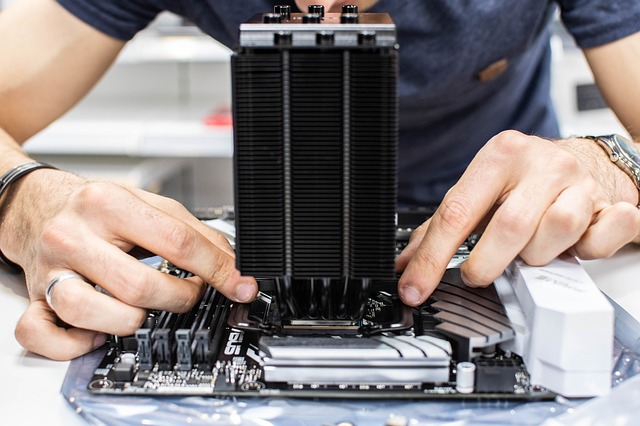

Prototyping & Testing

We specialize in rapid prototyping and comprehensive testing services to accelerate product development and ensure consistent performance and reliability. From early-stage proof-of-concept builds to pre-production units, our process enables quick iteration and refinement. Our in-house team conducts extensive functional, electrical, thermal, and environmental testing to identify and resolve issues early, minimizing risk and reducing time-to-market. With capabilities in DFM (Design for Manufacturability) analysis, compliance validation, and reliability testing, we ensure that each prototype not only meets design intent but is fully prepared for scalable production.

PCB Assembly (SMT & THT)

We provide end-to-end PCB assembly services utilizing both Surface Mount Technology (SMT) and Through-Hole Technology (THT) to meet a wide range of design and production needs. Our advanced manufacturing setup enables accurate component placement, automated soldering processes, and strict quality control. From single prototypes to large-scale production runs, we ensure every board meets the highest standards of reliability and performance. Our expertise spans double-sided assemblies, mixed-technology boards, fine-pitch components, and RoHS compliance—delivering cost-effective, timely solutions tailored to your product requirements.

End-to-End Product Design

We offer comprehensive product design services that take your idea from initial concept to full-scale production. Our experienced team manages every phase of development—including product ideation, schematic and circuit design, PCB layout, 3D modeling, prototyping, firmware and embedded software development, mechanical design, and system-level integration. With a strong focus on performance, manufacturability, and cost-efficiency, we ensure your product is not only functional and reliable but also optimized for market success. Whether you’re developing a new innovation or refining an existing product, we provide the technical expertise and cross-functional collaboration needed to bring your vision to life.

Box Build & System Integration

We provide comprehensive box build and system integration services that go beyond PCB assembly to deliver fully assembled, ready-to-deploy electronic systems. Our capabilities include enclosure assembly, cable and wire harness installation, sub-system integration, thermal management, labeling, and final functional and quality testing. Whether it’s a simple product enclosure or a complex electromechanical system, we manage the entire process—from component sourcing to final packaging—with a strong focus on precision, scalability, and reliability. Our turnkey solutions are customized to meet your unique technical and commercial requirements, helping you reduce time-to-market and streamline production workflows.

Prototyping & Testing

We specialize in rapid prototyping and comprehensive testing services to accelerate product development and ensure consistent performance and reliability. From early-stage proof-of-concept builds to pre-production units, our process enables quick iteration and refinement. Our in-house team conducts extensive functional, electrical, thermal, and environmental testing to identify and resolve issues early, minimizing risk and reducing time-to-market. With capabilities in DFM (Design for Manufacturability) analysis, compliance validation, and reliability testing, we ensure that each prototype not only meets design intent but is fully prepared for scalable production.